Roadmap

Fast creation of enterprise-level business applications

Solutions

Download a complete presentation about the company with case descriptions, functional and technical features in a convenient format.

Leave a request and our specialists will contact you with all the details for a free demonstration of the no-code 3V platform

A system for developing balanced and optimized production plans, financial plans and investment plans for your departments and the assets controlled by them

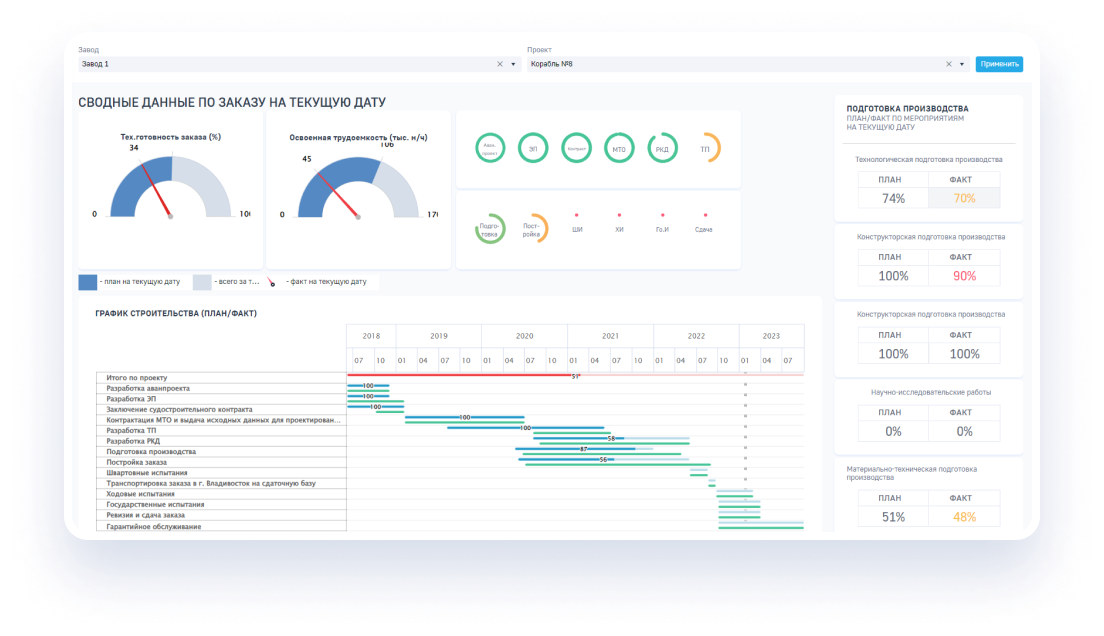

The system is designed to automate the process of collecting production reports

The system is designed for operational management decision making. Standard reports with flexible customization of formulas for calculating indicators are available

We create and develop software products that simplify business process management

3v.app partners are high-class experts in the development and implementation of BPM, RPA and low-code technologies

Download a complete presentation about the company with case descriptions, functional and technical features in a convenient format.

Requesting Demo Access

Request access to our demo stands. It's absolutely free.

We do not share or publish your information. Read more in our privacy policy

Request for solution development

We do not share or publish your information. Read more in our privacy policy

Запрос на демо-доступ

We do not share or publish your information. Read more in our privacy policy

Запросить цену

We do not share or publish your information. Read more in our privacy policy

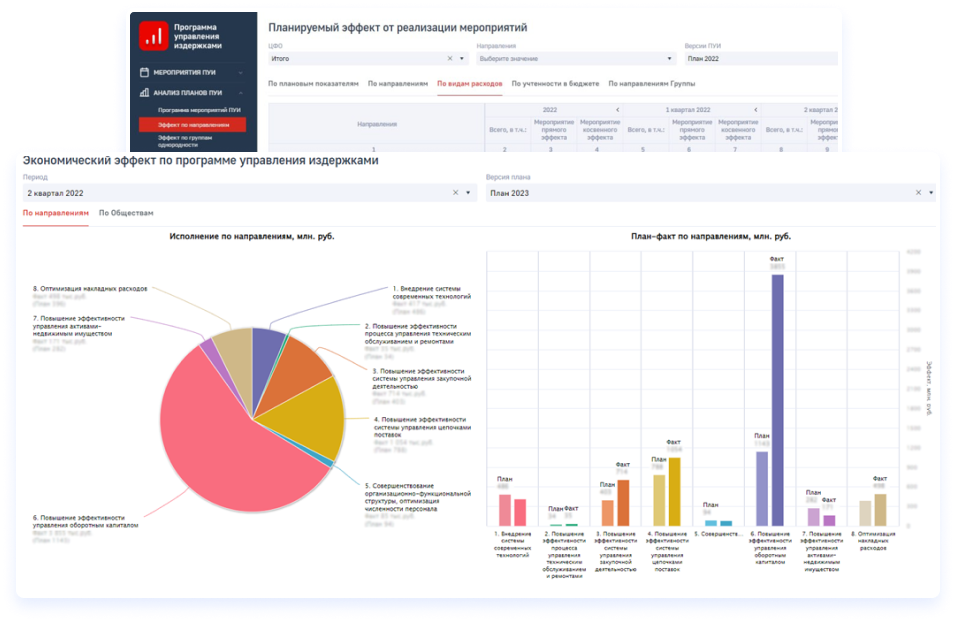

Cost management and operational efficiency program

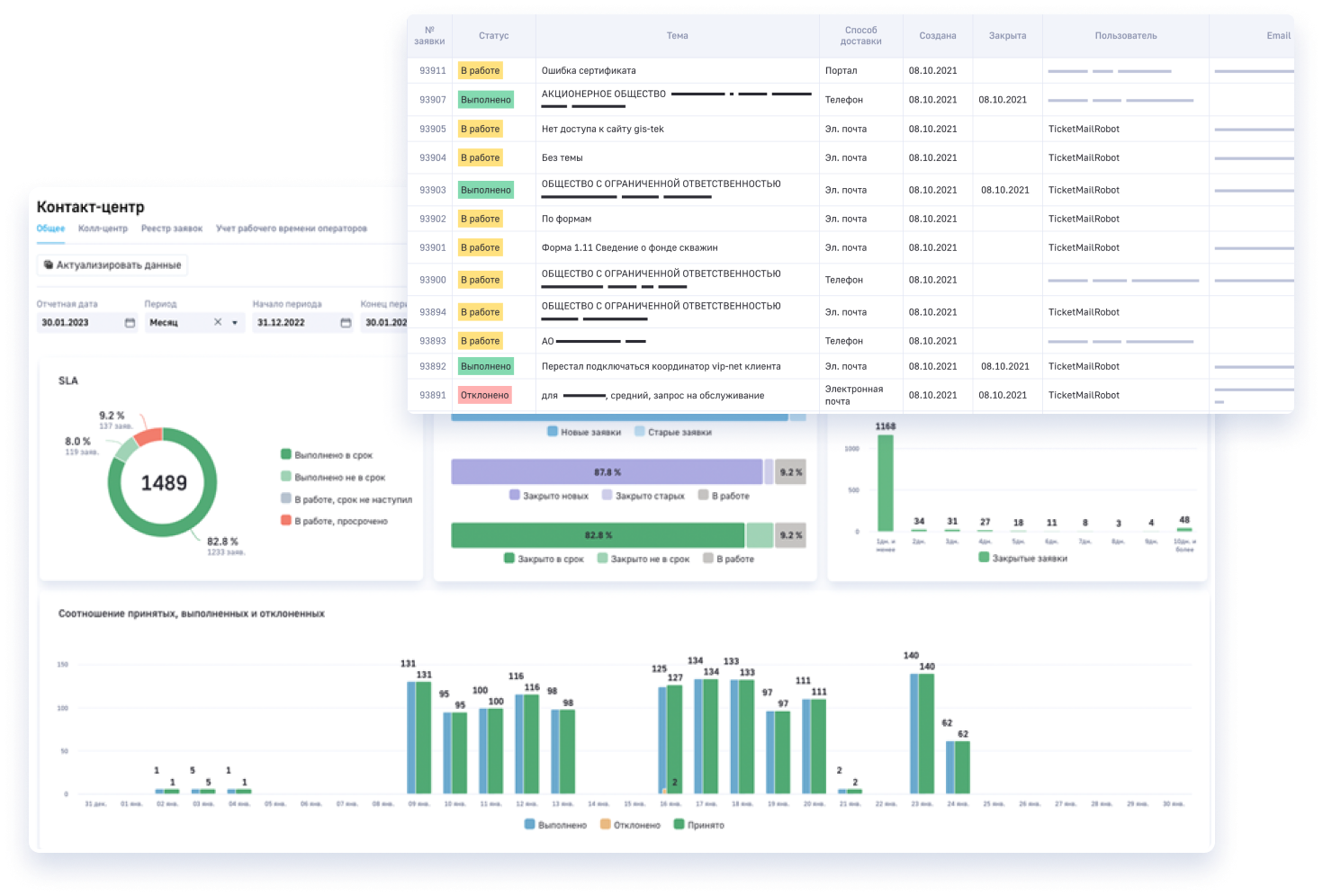

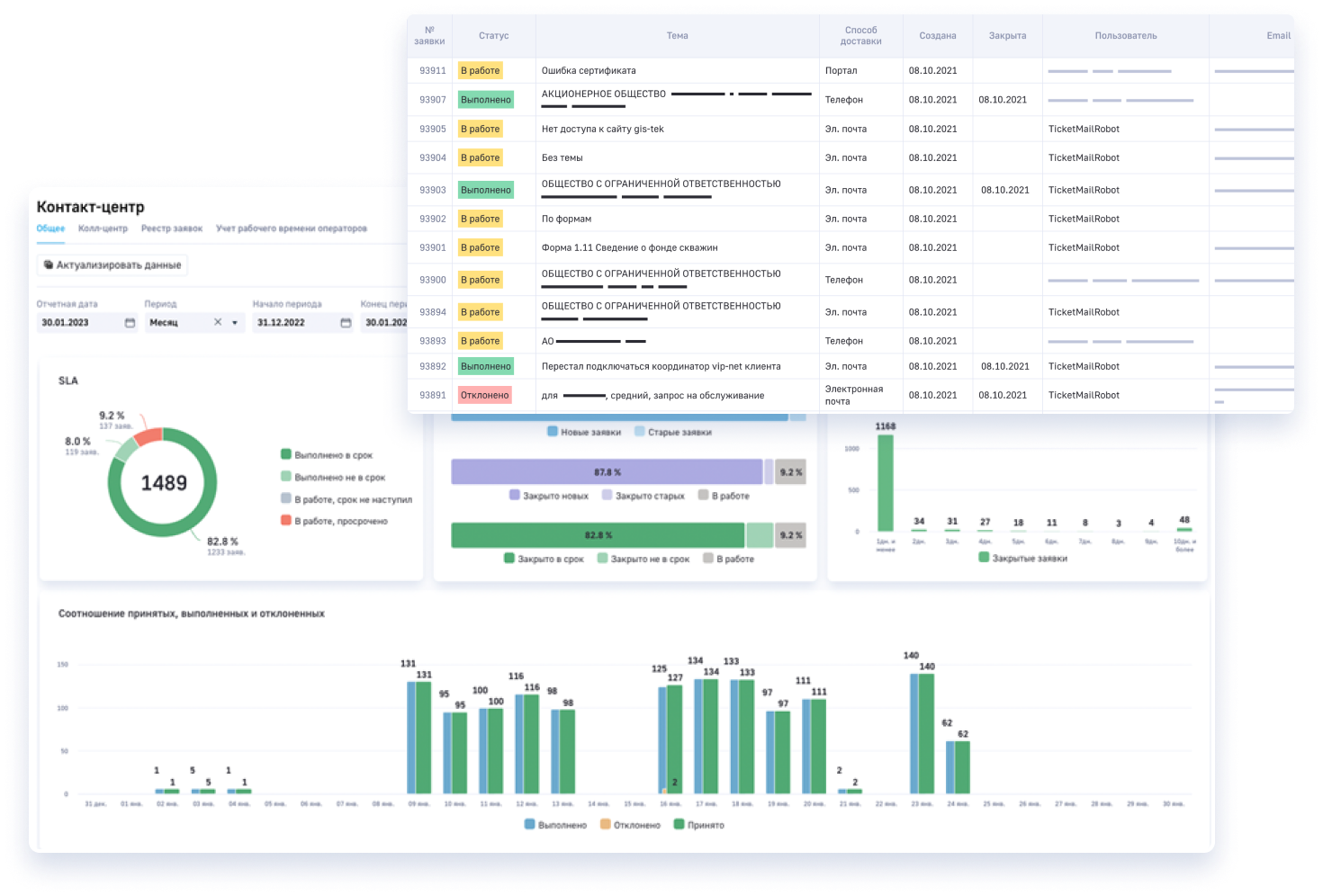

A system designed for operational management decision-making. Standard reports with flexible customization of the calculation formulas of the indicators. The system of data access control provides information security that meets modern standards

Case overview

Aim

Tasks

Improve the quality and efficiency of management decision-making regarding cost management and operational performance

1

Standardization and reduction of labor in the process of collecting and forming indicators of the Cost Management Program

Ensure completeness, reliability, homogeneity and consistency of data throughout the analyzed indicators

2

3

Provide multi-user access to a single source of information on the Cost Management Program

Register of typical activities of performance improvement

Solutions

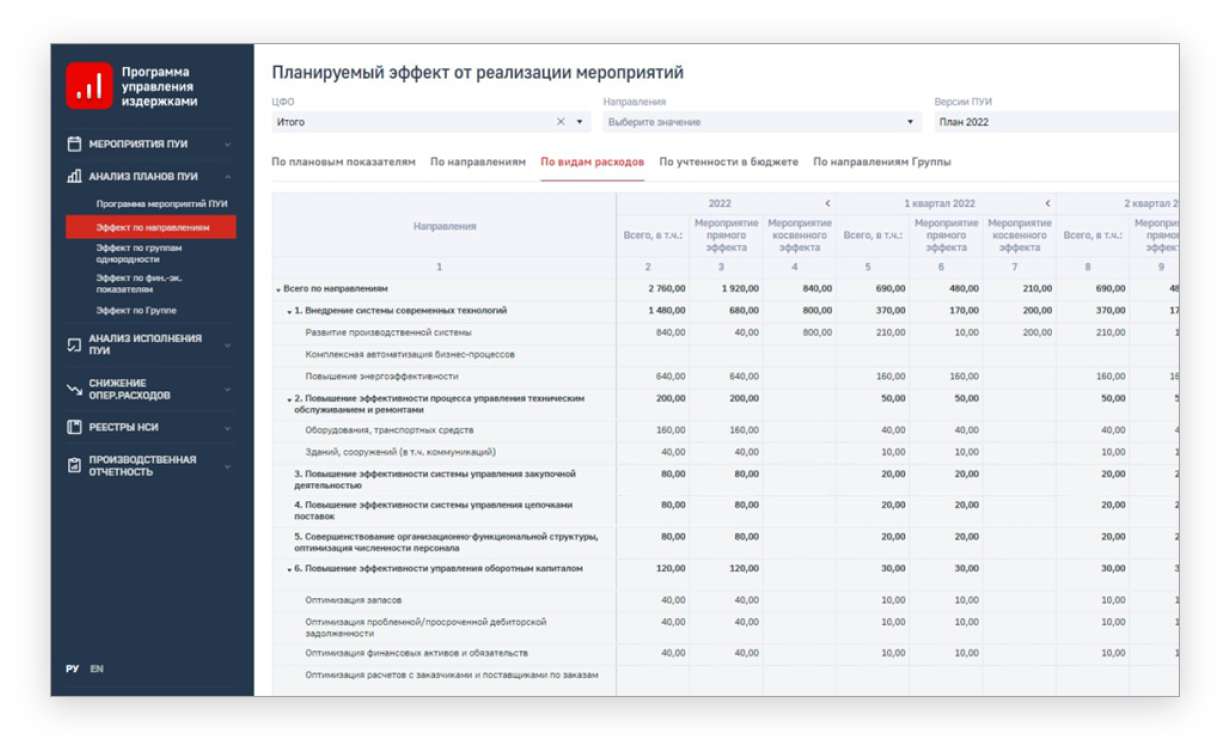

Register of events with flexible filtering and sorting options

Detailed view of events and history of changes in data

Flexible configuration of access rights to confidential information

Calculation of various indicators by a number of formulas

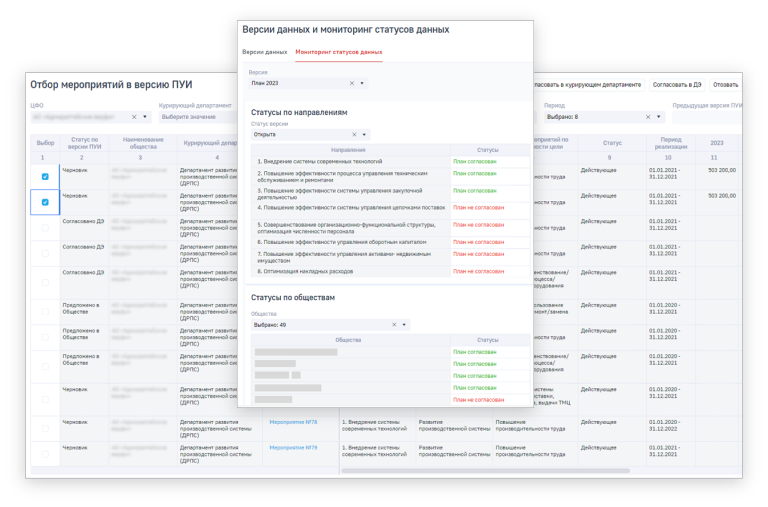

Electronic reconciliation and approval of activities

Visual report on the status of events by departments and entities

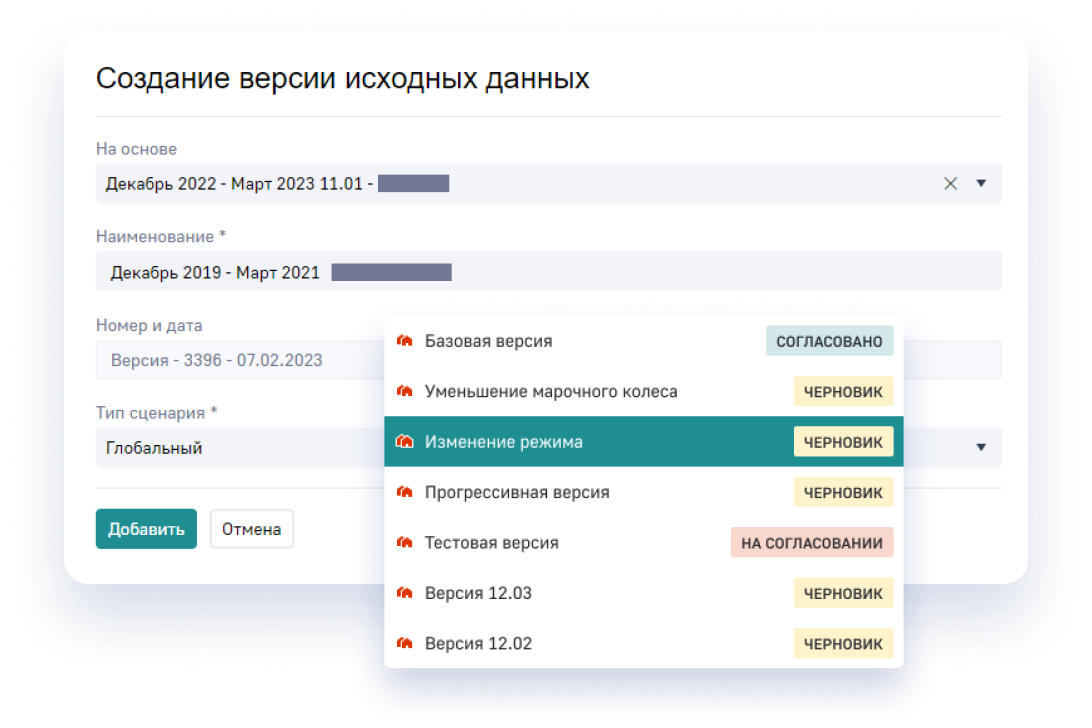

Data version control

Business processes and reconciliation schemes

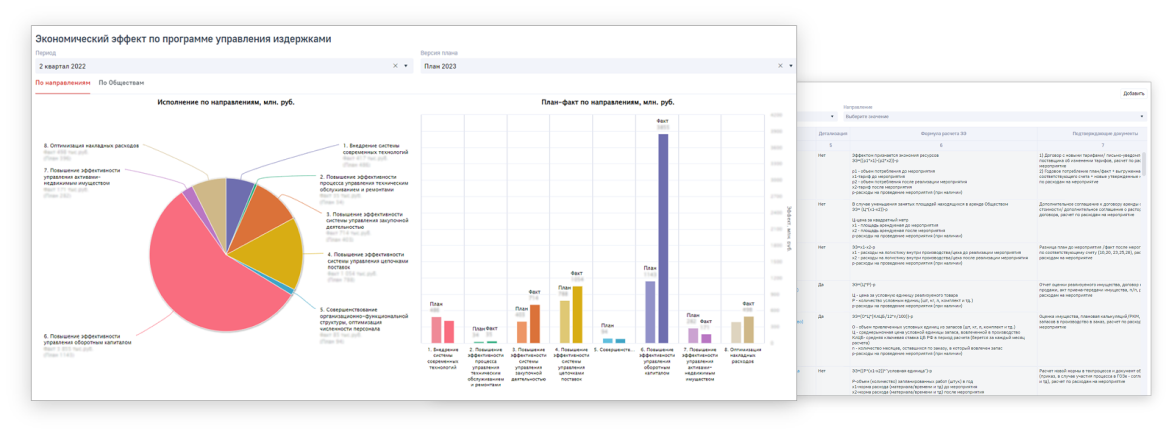

Generation of analytical reports and dashboards on planned and actual programme indicators

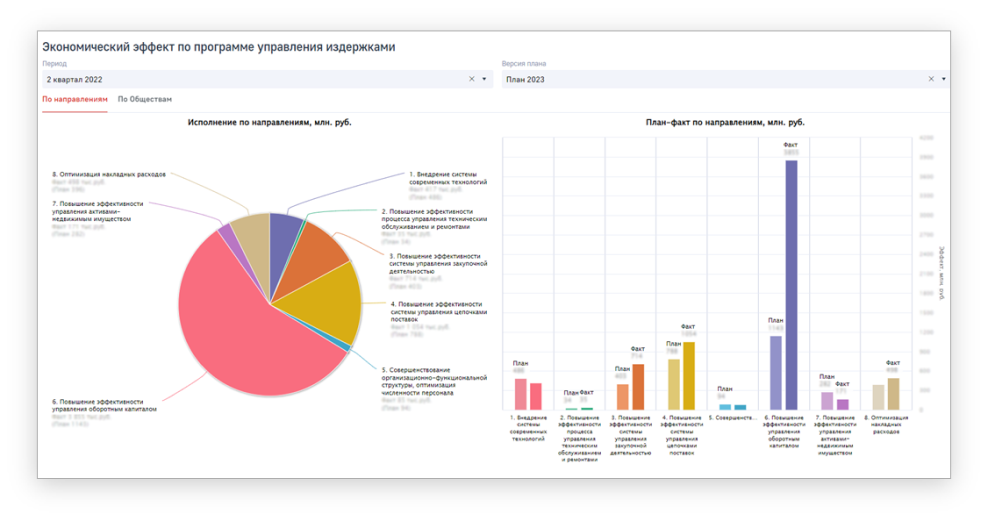

Analysis of the performance of planned and actual indicators for the selected period

Analysis of different versions of the plan and real-time calculation of economic impact of measures

Analysis of the implementation of planned and actual values in terms of optimisation areas

Results:

Company departments and units responsible for monitoring and consolidating data on the company's proposed activities

Financial and economic management at the Group level, which checks, analyzes and agrees on proposals for the company's activities

Specialists responsible for creating a list of measures and planning data for including them in the Group's Cost Management Program

Automation of entire company operations

Automation of the activities of the supervising departments at Group level that carry out the verification, analysis and approval of activities

Organised data collection from external sources. Set up analytical indicator calculations and added controls. Prepared analytical monitors and reports on individual analytical indicators

We have developed a system designed to automate production reporting processes, such as monitoring of shop floor plans, staffing levels, dynamics of the plan, production status, etc.

The system is designed for comprehensive automation of the processes of generating managerial and analytical reporting for a company. The system is designed for medium and large companies

Other cases