Roadmap

Fast creation of enterprise-level business applications

Solutions

Download a complete presentation about the company with case descriptions, functional and technical features in a convenient format.

Leave a request and our specialists will contact you with all the details for a free demonstration of the no-code 3V platform

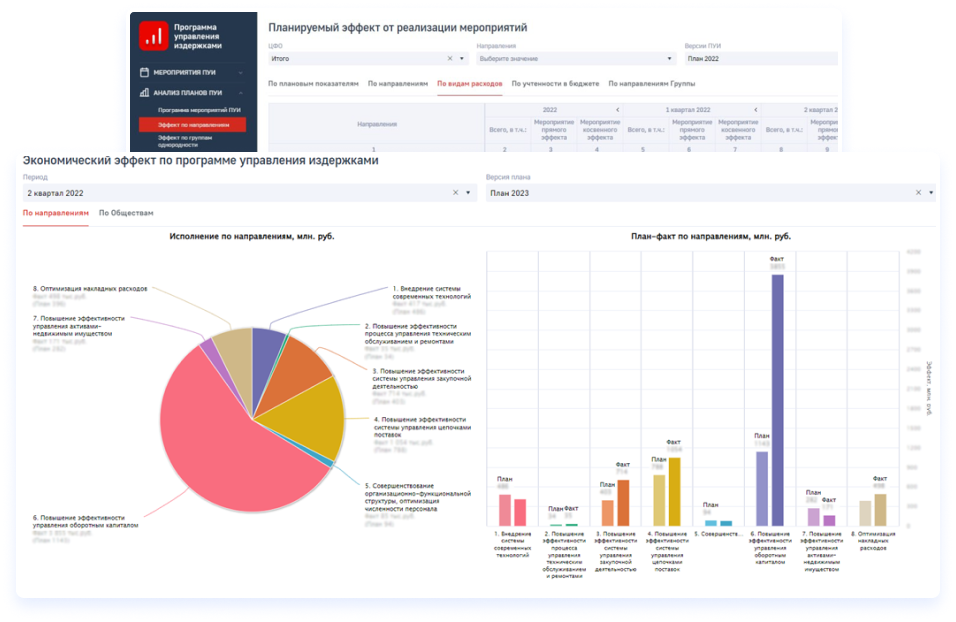

A system for developing balanced and optimized production plans, financial plans and investment plans for your departments and the assets controlled by them

The system is designed to automate the process of collecting production reports

The system is designed for operational management decision making. Standard reports with flexible customization of formulas for calculating indicators are available

We create and develop software products that simplify business process management

3v.app partners are high-class experts in the development and implementation of BPM, RPA and low-code technologies

Download a complete presentation about the company with case descriptions, functional and technical features in a convenient format.

Requesting Demo Access

Request access to our demo stands. It's absolutely free.

We do not share or publish your information. Read more in our privacy policy

Request for solution development

We do not share or publish your information. Read more in our privacy policy

Запрос на демо-доступ

We do not share or publish your information. Read more in our privacy policy

Запросить цену

We do not share or publish your information. Read more in our privacy policy

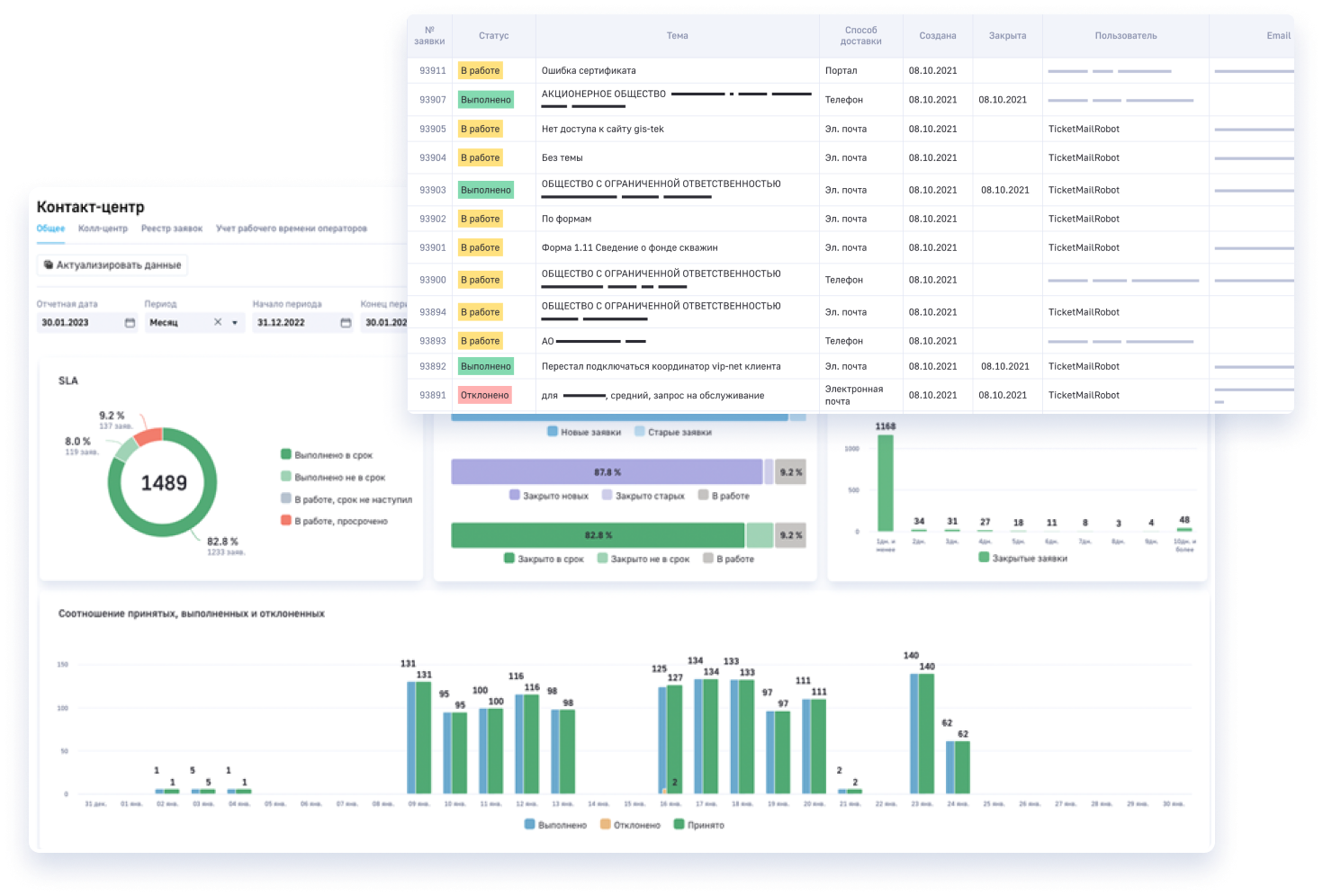

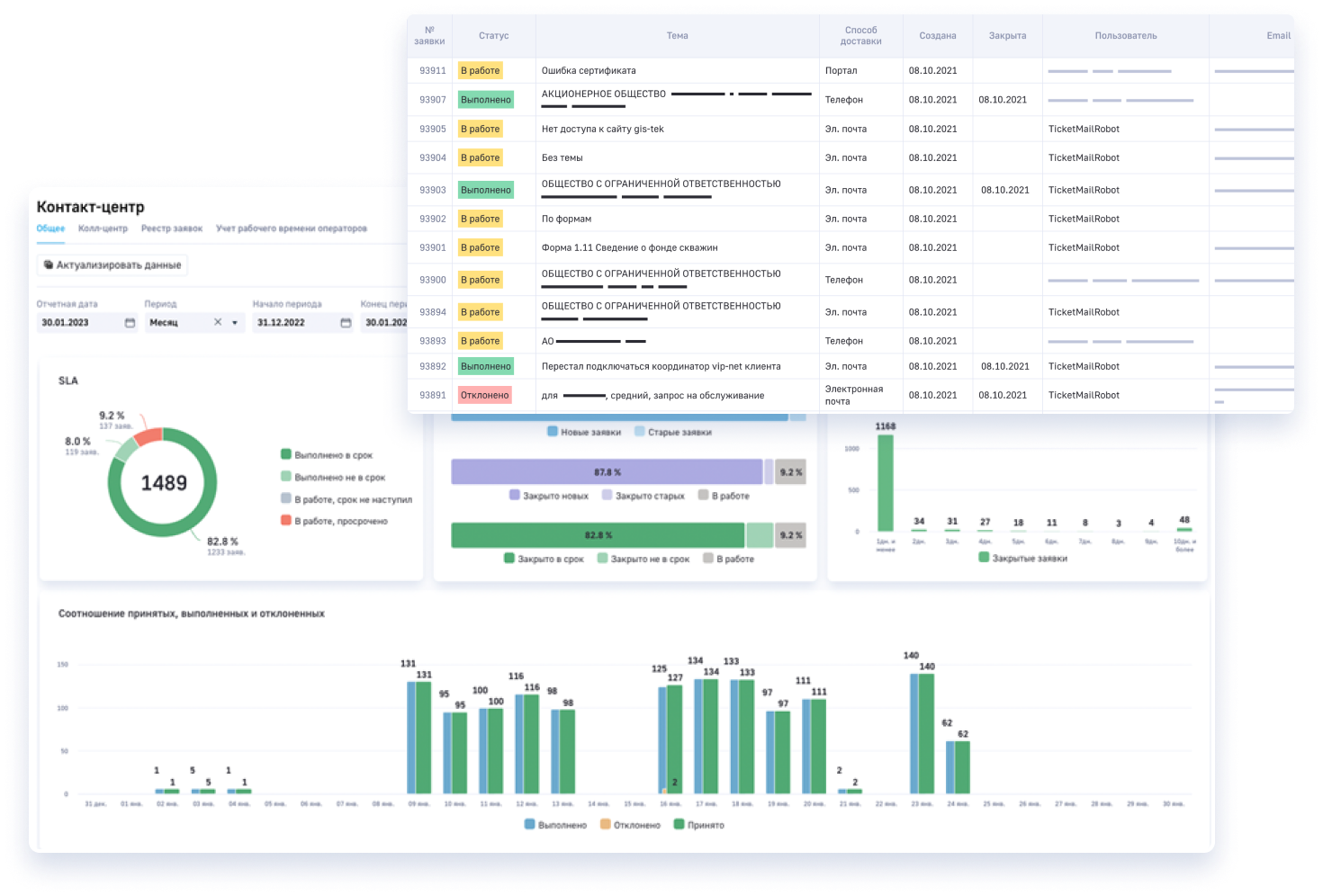

Cases on the 3V Platform

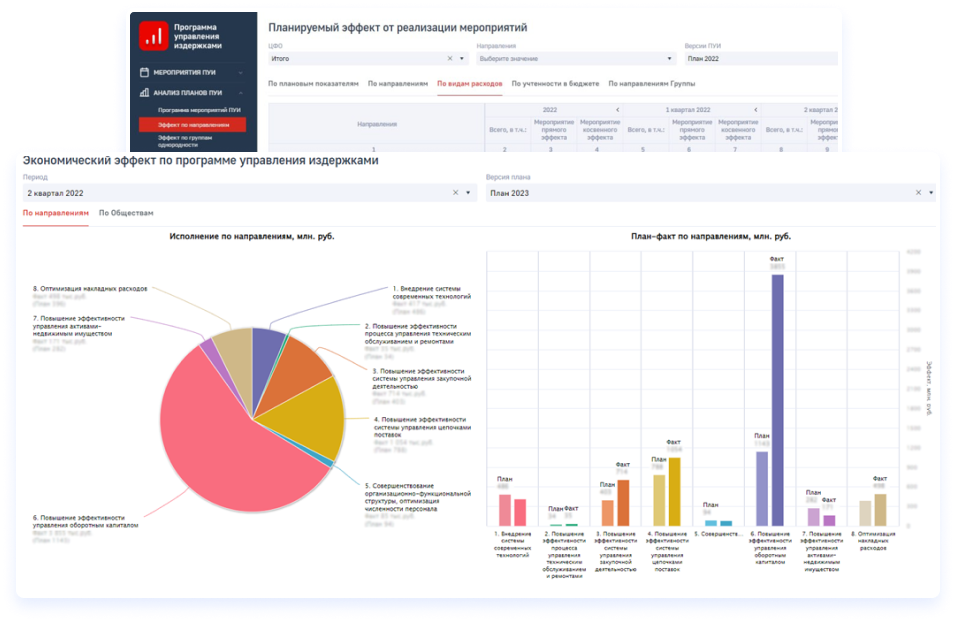

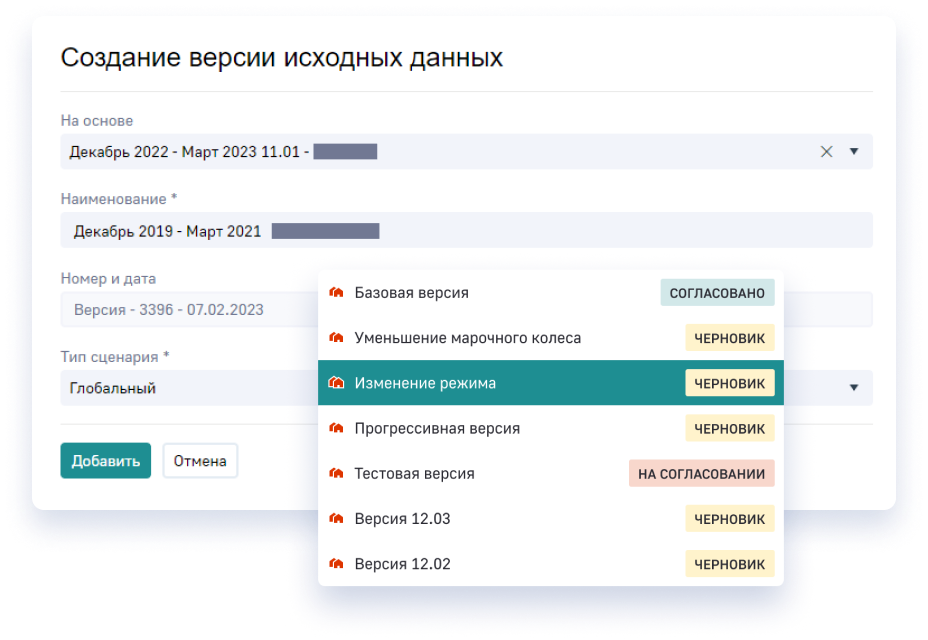

The system is designed to develop balanced and optimised production, financial and investment plans at the level of company divisions and the assets under their control. It also generates consolidated plans for the company as a whole

We have automated production reporting processes such as monitoring of shop floor plans, staffing levels, progress against plans, production status, etc. in a large shipbuilding company

In 8 months, we created an easy-to-use system that met all the client's criteria. It requires no technical skills and every employee can now use it with ease and be efficient.

A system designed to optimise the process of collecting, matching input data and production constraints

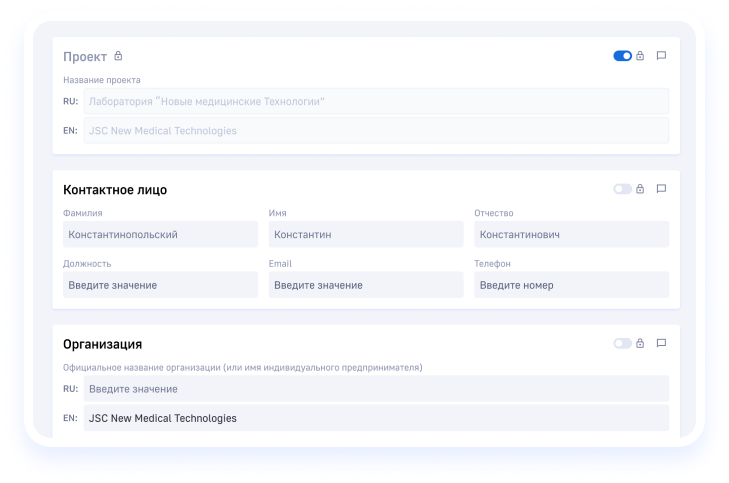

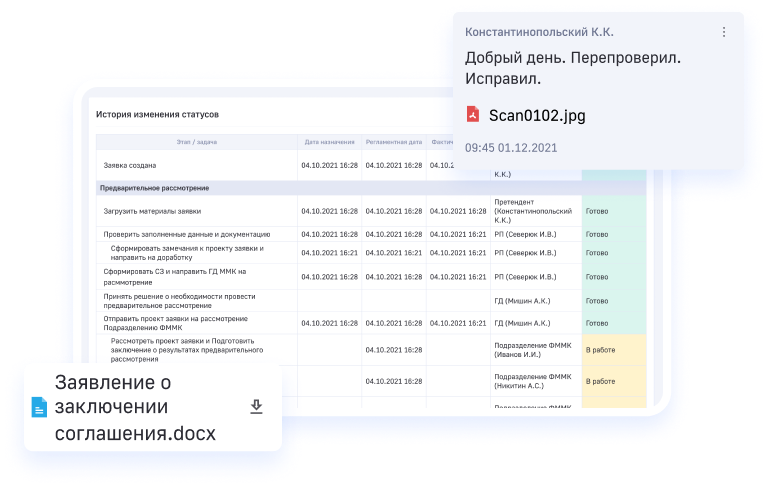

Developed a system designed to optimise the internal processes of a medical fund and automate business processes in a short timeframe.

In the process, the foundation was faced with an urgent need to automate the processing, systematisation and approval of potential project participants' materials.

In the process, the foundation was faced with an urgent need to automate the processing, systematisation and approval of potential project participants' materials.

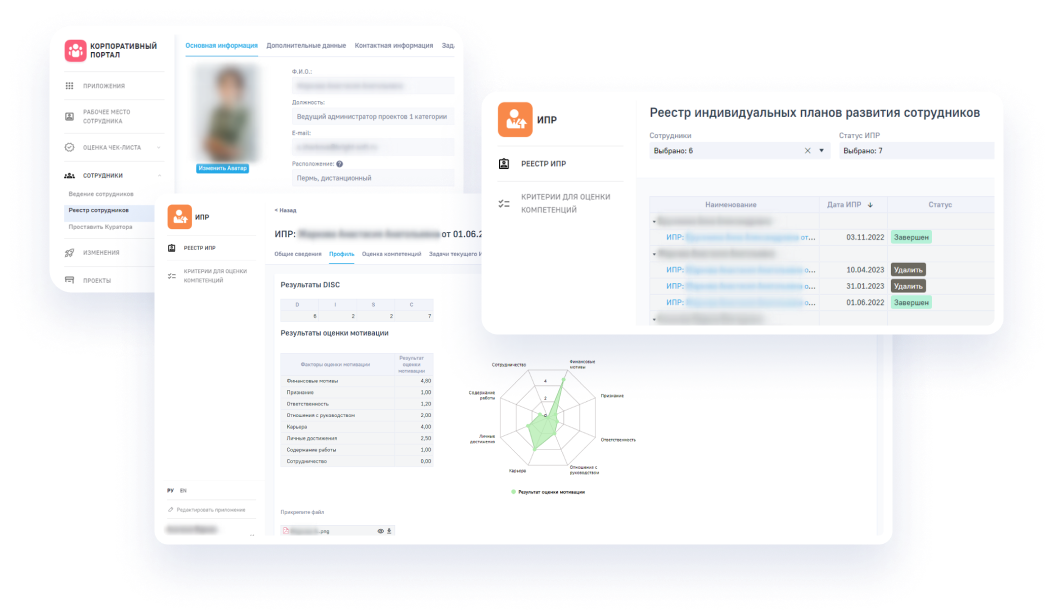

The application suite can operate as an integrated human resource management system and address a wide range of tasks, from managing the recruitment process to making managerial decisions based on an employee's psycho-emotional profile.

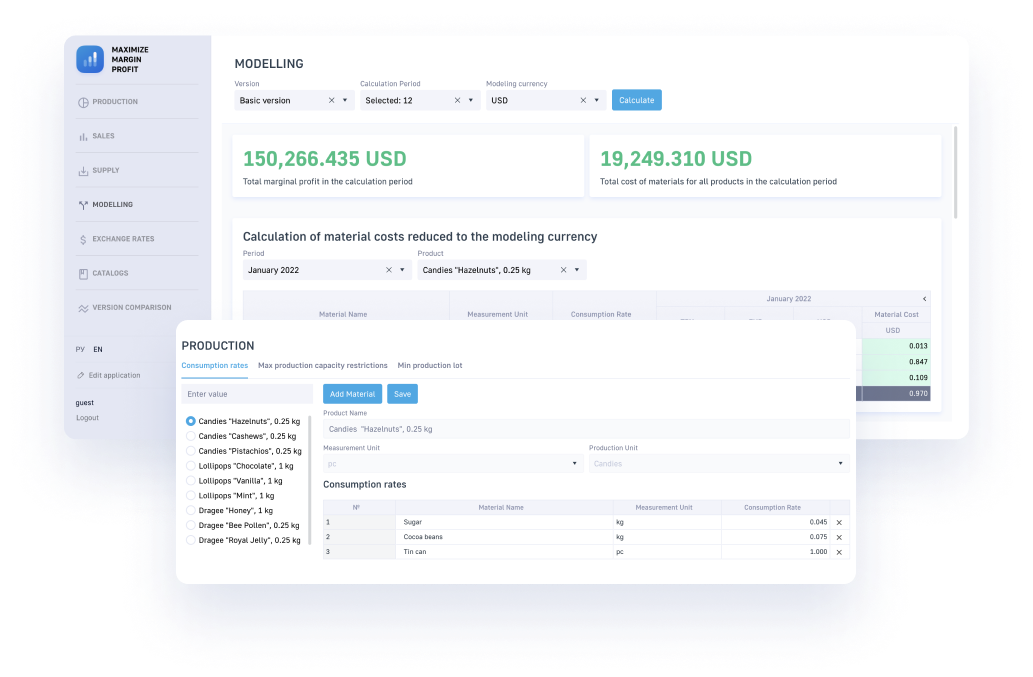

An application to help businesses maximize their margins, optimize business processes and improve decision-making. Its main purpose is to provide companies with tools to effectively manage all aspects of their operations and improve margins